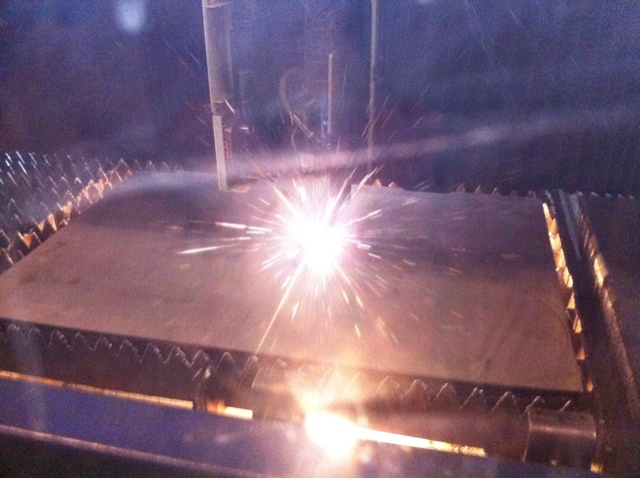

I Stopped by Laser Concepts Inc. this morning to see about the feasibility of getting my parts cut after last nights failure with the CNC plasma. Jake at LC loaded my files, looked them over and said 'sure'. He proceeded to send the cut program to the enormous laser table and cut them while i waited. Wow I couldn't believe they were getting cut right here right now. I'm not used to things going smoothly like this without some kind of headache or set back.

He knew right away the parts were for a motorcycle and he could see my excitement. We bonded over common gearhead ground and talked about some of his projects and my plans with these parts.

Starting with a thought and a simple paper sketch to create a precise computer drawing. Next printing a copy and tracing it to a chip board template to check the fit and finally a finished laser cut part in carbon steel. It's very rewarding to see the progression and hold the finished part.

It's a good day!

Wednesday, November 02, 2011

Tuesday, November 01, 2011

Photochoppin

Tyler and I have been kicking around the idea of sectioning my shoebox by cutting the car length wise and removing some height in the body. I threw together some photoshop images to get an idea.

Here is the car now

Here's a 2" section removed from the body

Here's a wedge section going from 2" in the rear to 0" in the front

It may happen once the bike is complete. We'll just have to see how it goes.

Here is the car now

Here's a 2" section removed from the body

Here's a wedge section going from 2" in the rear to 0" in the front

It may happen once the bike is complete. We'll just have to see how it goes.

TwoWheelTuesday

Lil Bits

I've been working on lots of small detail projects when I'm not in the shop.

Wanted to clean up my cast points cover and dress down the machined oil feed.

Started by media blasting both parts at Franks house.

Frank then took over polishing the points cover while I worked on the oil feed.

I wanted to de-billet my billet oil feed since all the other parts are cast, it didn't look right.

Wanted to clean up my cast points cover and dress down the machined oil feed.

Started by media blasting both parts at Franks house.

Frank then took over polishing the points cover while I worked on the oil feed.

I wanted to de-billet my billet oil feed since all the other parts are cast, it didn't look right.

Trunk Release

Putting form over function can almost always cause a few issues. Case in point when you shave the trunk handle and key lock how does one then actually open the trunk?

Here's one solution.

Tyler designed this pattern and cut it on the CNC plasma. A little welding and tada new trunk release lever which is mounted inside the car and opens the trunk via an attached length of wire cable.

Here's one solution.

Tyler designed this pattern and cut it on the CNC plasma. A little welding and tada new trunk release lever which is mounted inside the car and opens the trunk via an attached length of wire cable.

...like a hole in the head

Well I needed another project about as much as I need a hole in the head but here we go again...

Triumph project #2

It looks pretty bad because it is but I've got enough parts to put it back together.

I'm really thinking about a Cafe style build which will really minimize the mods and fabrication.

Triumph project #2

It looks pretty bad because it is but I've got enough parts to put it back together.

I'm really thinking about a Cafe style build which will really minimize the mods and fabrication.

Labels:

"shop projects",

"Two Wheel Tuesday",

Motorcycles

Saturday, October 29, 2011

Film

Put together this trailer for the short film I'm putting together from the footage I shot at Speedweek hanging with the Lowbrow Customs guys.

Wednesday, October 05, 2011

Progress

Monday, October 03, 2011

Tank

Wednesday, September 28, 2011

Monday, September 26, 2011

Back to work

Working on the Triumph again.

Installed the new bars after we cut 1.5" off each end to bring them in.

Took a brand new clutch lever and cut it up too.

We took out just under 1.5".

Mocked it up to check the fit.

Good to go so Tyler TIG welded the aluminum back into one piece.

After a little flap disc magic... Good as new short clutch lever.

Can't help but want to modify every little piece. Off the shelf simply will not do for this build.

Installed the new bars after we cut 1.5" off each end to bring them in.

Took a brand new clutch lever and cut it up too.

We took out just under 1.5".

Mocked it up to check the fit.

Good to go so Tyler TIG welded the aluminum back into one piece.

After a little flap disc magic... Good as new short clutch lever.

Can't help but want to modify every little piece. Off the shelf simply will not do for this build.

Labels:

"shop projects",

Garage,

Motorcycles,

Triumph

Subscribe to:

Comments (Atom)